Insider Tips for Getting the Most Out of litho printing

Insider Tips for Getting the Most Out of litho printing

Blog Article

A Comprehensive Guide to Comprehending Litho Printing Strategies

The globe of litho printing, a method stemming from the late 18th century, is a fascinating blend of background, science, art and advancement. Stay with us as we journey into the exciting realm of litho printing.

The Historical Development of Litho Printing

The historic trajectory of litho printing, a crucial development in the realm of interaction, is a captivating tale of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this method was originally an affordable method of publishing theatrical works. Lithography, derived from the Greek words for 'stone' and 'to compose', made use of a smooth stone surface to transfer images onto paper. The process developed with the introduction of the rotary press, which substantially increased productivity (litho printing). In the 20th century, the development of balanced out lithography changed the sector, enabling for automation of premium prints. Each phase of litho printing's advancement showcases mankind's unrelenting search of effectiveness and high quality in visual communication.

Decoding the Science Behind Litho Printing Inks

Moving on in the expedition of litho printing methods, the focus now shifts to the scientific research behind litho printing inks. The structure of these inks, their drying process, and shade mixing methods create the backbone of this complex art kind. Recognizing these elements is vital to mastering the craft and accomplishing the wanted print outcomes.

Make-up of Litho Inks

In lithographic printing, the basic function of litho inks can not be overemphasized. Pigments, the color-providing aspects, are finely ground fragments suspended in the car, a liquid that lugs the pigment onto the printing surface. Each component plays a vital part in the final print's high quality, making the exact formulation of litho inks an elaborate scientific research.

Ink Drying Process

From the structure of litho inks, interest transforms to the interesting process of ink drying. Two key approaches are used in litho printing: oxidative drying and absorption. Absorption, on the various other hand, includes the ink leaking into the paper fibers, which is a quicker process but can lead to less vivid shades.

Color Mixing Techniques

While the drying out procedure plays an essential role in litho printing, the scientific research of color blending techniques holds equivalent value. This is a complicated process that includes the careful mixing of main shades: cyan, magenta, and yellow, in varying proportions to accomplish a broad selection of colors. The addition of black ink, referred to as 'essential', aids in controling the strength and depth of the shades. The science behind litho printing inks additionally takes into account the openness of the ink, which impacts how shades overlay and mix. To accomplish an efficient shade mix, print specialists must additionally comprehend the intricacies of ink actions, color theory, and the physical properties of the substrate on which the ink is used.

The Art and Design Elements in Litho Printing

Litho printing breathes life into art and design with its one-of-a-kind components. Litho printing accommodates a variety of colors, enabling musicians to develop dynamic and vibrant prints. This mix of precision and adaptability makes litho printing a favored choice for several musicians and designers.

Modern Applications of Litho Printing Techniques

Litho printing strategies have found extensive usage in the contemporary commercial sector. Its influence and importance continue to expand with the arrival of brand-new advancements and technologies in the area. This section will certainly discover these modern applications and the transformative role they play in the printing sector.

Commercial Litho Printing Utilizes

Litho printing continues to be an essential part of the commercial industry. High-volume printing tasks, such as the production of books, newspapers, and packaging, rely on litho printing for its capability to provide remarkable picture high quality and expense performance. Litho printing also provides a wide shade range, exceptional to that of electronic printing.

Developments in Litho Printing

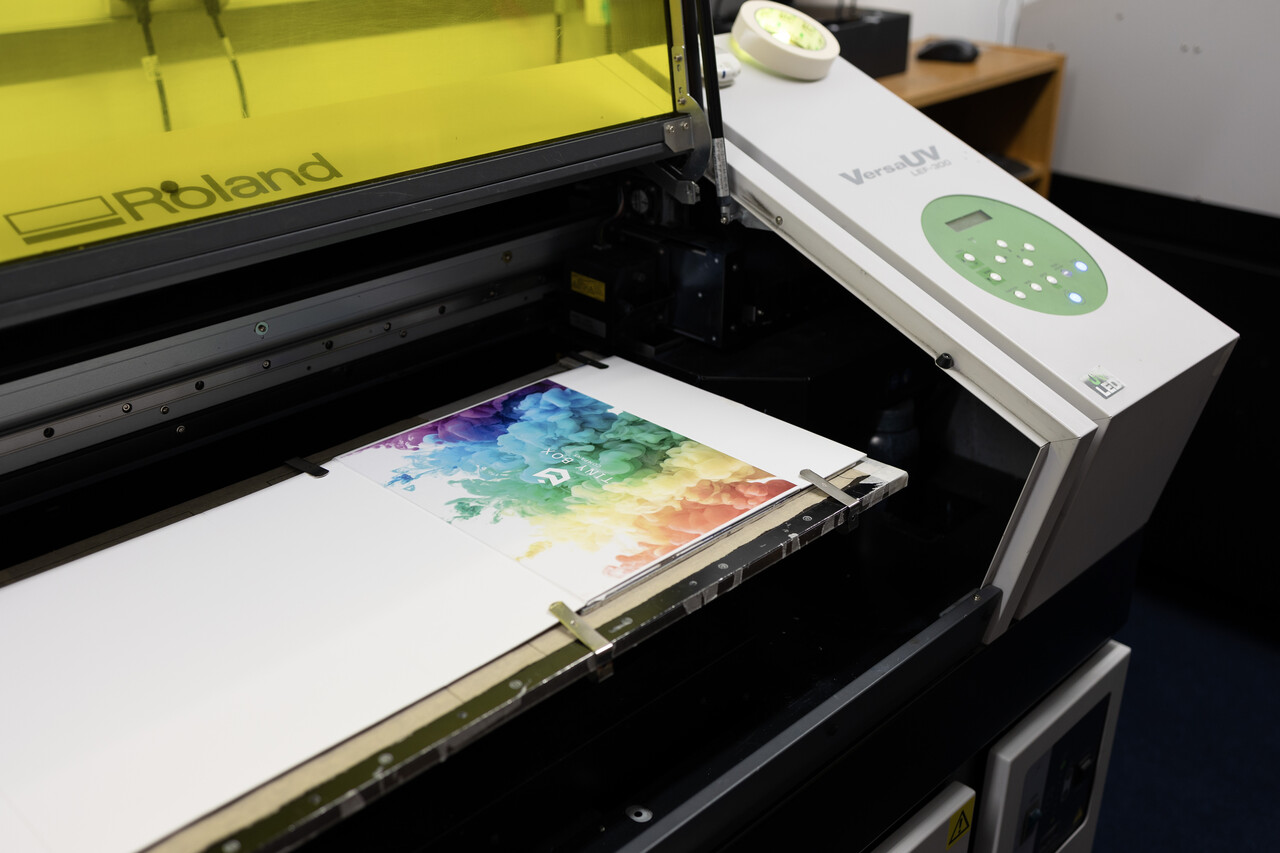

Pressing the boundaries of conventional methods, contemporary improvements have fueled a host of innovations in litho printing. These innovations have not just enhanced the high quality and efficiency of litho prints but additionally broadened its application scope. One prominent growth is electronic litho this post printing, which integrates the virtues of electronic modern technology with litho's high-grade outcome. This hybrid version uses faster configuration times, decreased waste, and makes it possible for on-demand printing. One more notable advancement is the intro of eco-friendly inks. These inks, made from veggie or soy-based solutions, have dramatically decreased the industry's ecological effect. litho printing. Additionally, the development of advanced plate modern technology has streamlined the printing procedure, leading to sharper photos and improved shade fidelity. These technologies highlight the long-lasting relevance of litho Going Here printing in the modern-day world.

Checking out the Refine of Litho Printing: Step by Step

Challenges and Solutions in Contemporary Litho Printing

In spite of the precision and custom that litho printing happily upholds, it is not without its set of modern challenges. The most common concerns consist of the high initial configuration price, difficulty in printing variable data, and environmental worries as a result of chemical usage. Remedies are arising as technology develops. Digital litho printing enables for economical brief runs and very easy personalization, attending to the problem of variable information. Environmentally-friendly inks and more secure plate-making processes mitigate environmental issues. Furthermore, developments in automation have minimized labor expenses, additionally equalizing the lithography procedure. Therefore, while there are obstacles, the litho printing sector is proactively adjusting to fulfill them head-on, guaranteeing its importance in the future.

Verdict

In verdict, litho printing, with its rich history and clinical complexities, holds a substantial area in the print market. As the guide discloses, it's a synthesis of art and technology, with modern-day innovations guaranteeing its relevance. However, the sector deals with challenges that call for ingenious services, with an emphasis on automation and sustainability. The future of litho printing rests on its capacity to adapt to these transforming demands, attesting its Look At This long-lasting value in an advancing market.

Report this page